I. Introduction:

This machine is a computer-controlled high-efficiency and high-precision special equipment for bus bar processing (6-axis numerical control), which is mainly used for fully-CNC punching and shearing of copper-aluminum busbar, including punching, shearing, corner cutting, embossing and other processes. Manual intervention is not needed during the processing of the bus bar, which has the advantages of high processing speed, high precision and the like, and is widely applied to the industries of high and low voltage complete sets, switch cabinets, box-type transformer substations and the like.

II. Main features:

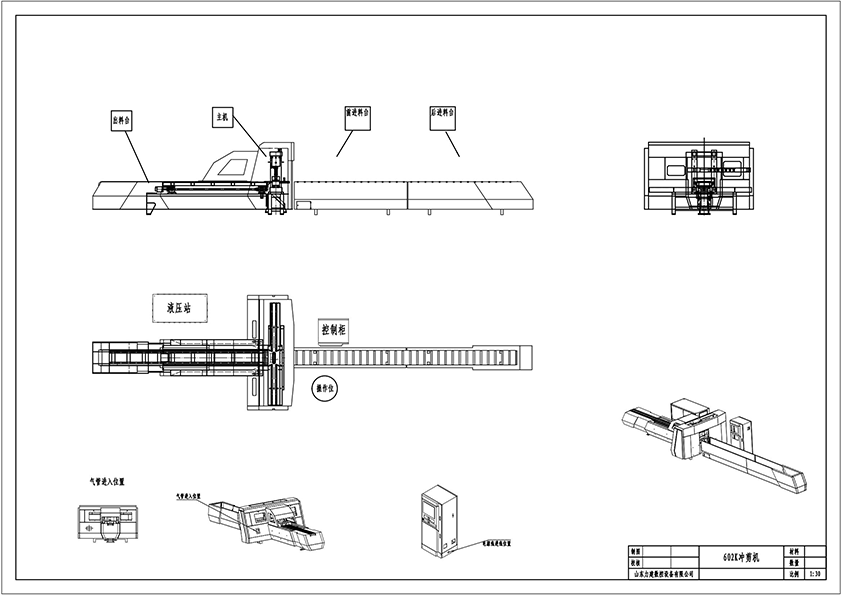

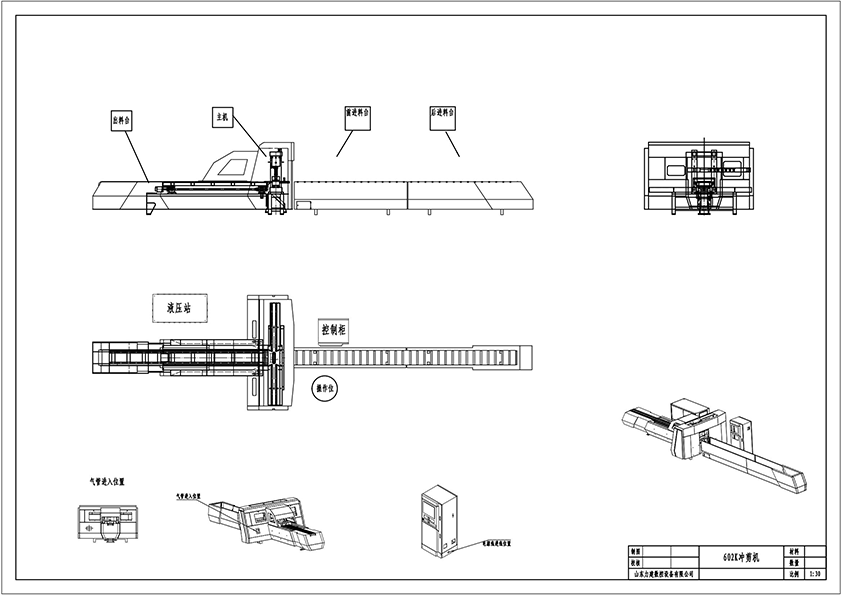

1. Feeding part:

The feeding part is equipped with the main and auxiliary power clamps of X1 and X2. The main clamp and the auxiliary clamp can operate independently and can be matched with each other to finish feeding work. This clamp structure avoids the situation that the auxiliary clamp of the same kind in China needs to be pushed back and forth by the main clamp servo when moving due to the lack of power of the auxiliary clamp, thereby leading to equipment failure and workpiece scrapping caused by bulging and bending of the small busbar during movement due to insufficient rigidity.

2. Mold movement part:

The mold movement part is in the spindle Y-axis and is mainly in the form of a servo motor driving ball screw to achieve reciprocating mold changing, thereby realizing the movement and positioning of the mold. The integral mold library has the characteristics of stable movement, accurate positioning and high speed.

3. Punch striking part: (Patent No.: ZL 2013 2 0804568. X)

The punch striking part is in the Z direction, and the servo motor drives the lead screw to move in the Z direction. The maximum strike speed is 150 beats per minute.

4. Mold library part: (Patent No.: ZL 2013 2 0804566.0; no waste materials after shearing, the only one in China)

The mold library part is a seven-punching-one-shearing-one-embossing or eight-punching-one-shearing in-line mold library. The shearing tool is a single-knife centering-type shearing, and the shearing effect is good without waste materials after shearing.

5. Hydraulic power part:

The hydraulic power part adopts double-speed double-pressure fast oil supply, with the maximum output of 600KN. The oil temperature sensor on the machine can accurately transmit the temperature of the oil to the radiator. When the temperature of the oil exceeds the set value, the radiator automatically starts to dissipate heat, ensuring the hydraulic system of the machine can run safely and effectively for a long time.

6. Electrical control part:

The advanced programmable controller of Beckhoff is adopted. During the working process, the point coordinate input mode can be selected for programming (it is simple to use and has low requirements for the operator). It can also realize the direct generation of CAD drawing to processing program, and can directly perform bending and unfolding operation and processing program simulation operation in the software.

7. LJCAM-02-2014.3 Programming Software: (Software Copyright Registration Certificate: 2014SR177566, originally obtained)

This software realizes the direct generation of CAD drawing to the machining program (the machining code is directly generated by the CAD drawing), and can directly perform bending and unfolding operation and processing program simulation operation in the software.

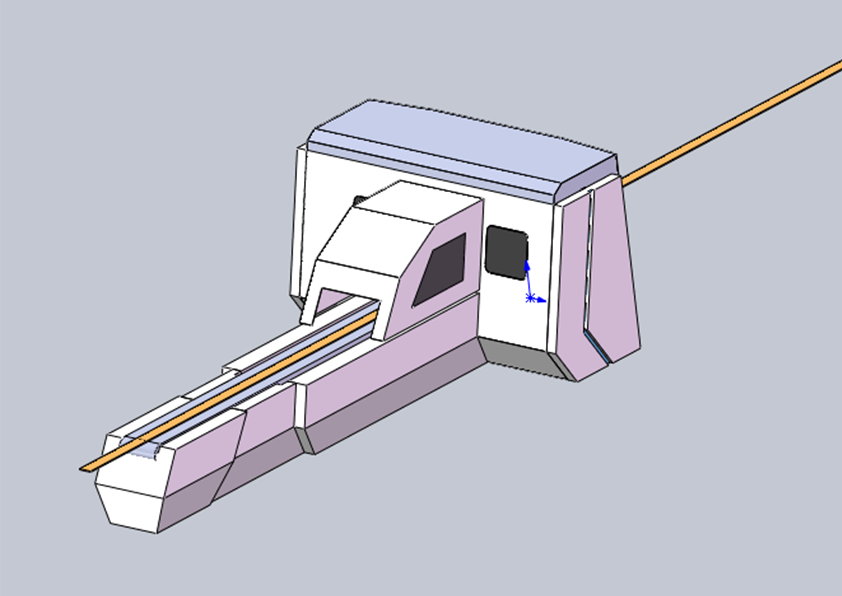

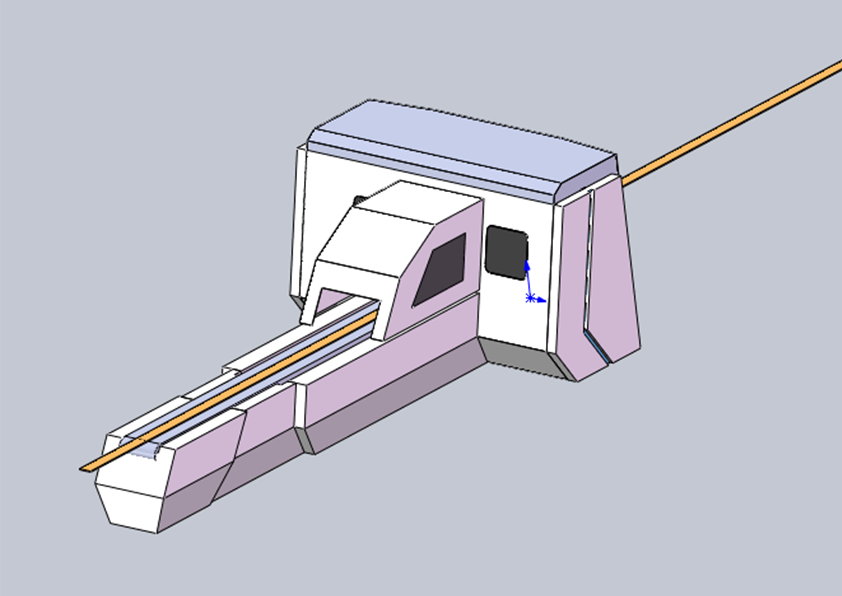

8. Appearance: The appearance design is novel and generous. (Patent No.: ZL 2014 3 0448531.8)

III. Main technical parameters:

| Number of mold positions | Punching unit | Piece | 7 | 8 |

| Shearing unit | Piece | 1 | 1 |

| Embossing unit | Piece | 1 | 0 |

| Beating frequency of main beating cylinder | HPM | 120-150bpm (20mm stroke) |

| Number of control axes | AXIS | 6 |

| Hole spacing control accuracy | mm/m | ±0.20 |

| Maximum punching diameter | mm | Ø4.3-35 (circular hole) |

| Maximum cross-sectional area | mm2 | 200×50 |

| Maximum positioning speed of X-axis | m/min | 75 |

| Maximum effective stroke of X-axis | mm | 2000 |

| X-axis accuracy error | mm | 0.20/500 (not accumulated) |

| Maximum positioning speed of Y-axis | m/min | 40 |

| Maximum effective stroke of Y-axis | mm | 960 |

| Y-axis accuracy error | mm | 0.20/500 (not accumulated) |

| Maximum stroke of Z-axis | mm | 310 |

| Stroke of punching cylinder | mm | 45 |

| Maximum allowable size | mm | 6000×200×15 (L×W×D) |

| Minimum allowable size | mm | 15×3 (W×D) |

| Area of main station: | mm | 10500×2900 (L×W) |

| Total power of power supply | kW | 25 |

IV. Selection of main accessories:

| Electrical part: |

| Serial No. | Name | Brand | Serial No. | Name | Brand |

| 1 | Main motor | ABB | 2 | Programmable controller | BECKHOFF, Germany |

| 3 | Servo motor | Rexroth | 4 | Intermediate relay | Honeywell |

| 5 | Servo driver | Rexroth | 6 | Computer | Beijing Qiyang |

| 7 | AC contactor | Siemens | 8 | Thermal relay | Siemens |

| 9 | DC power supply | Phoenix, Germany | 10 | Circuit breaker | Siemens |

| 11 | Inductive switch | BALLUFF, Germany | 12 | Linear displacement sensor | BALLUFF, , Germany |

| Transmission and hydraulic system: |

| Serial No. | Name | Brand | Serial No. | Name | Brand |

| 1 | Electromagnetic reversing valve | Rexroth, Germany | 2 | Proportional valve | Rexroth, Germany |

| 3 | Precision ball screw | HIWIN/TBI | 4 | Precision linear guide rail | HIWIN/PEK |

| 5 | High pressure oil pump | Albert, the United States |

|

|

|

V. Accessories:

8 sets of punching dies, 1 pair of scissors, 1 pair of embossing dies, 1 set of maintenance tools, instructions and certificate of conformity.

Lijian MX602K-7/8C Busbar Punching and Shearing Machine: Smart and Efficient Solution for Modern Busbar Fabrication

Introduction

The Lijian MX602K-7/8C Busbar Punching and Shearing Machine is a highly efficient and precise electrical Busbar processing machine engineered for power equipment manufacturers, switchgear production lines, and control cabinet assembly plants. Combining advanced punching and shearing capabilities into one integrated platform, this model significantly boosts production efficiency while ensuring excellent accuracy and repeatability.

Built by Lijian, a leading name in busbar machinery, the MX602K-7/8C is specifically tailored to meet the rising demands for automation, intelligence, and versatility in modern electrical processing facilities.

1. Product Overview

The MX602K-7/8C is a semi-automated or fully automated CNC busbar punching and shearing machine designed to handle copper and aluminum busbars of varying widths and thicknesses. It features servo feeding, dual-station hydraulic control, and an intelligent operation system that minimizes manual intervention and maximizes throughput.

Key Technical Parameters

| Parameter | Specification |

|---|

| Max Busbar Width | 200 mm |

| Max Busbar Thickness | 12 mm |

| Punching Force | 600 kN |

| Shearing Force | 800 kN |

| Punching Types | Round / Oblong / Custom Shapes |

| Max Shearing Length | 6 m |

| Feeding Mode | Servo Automatic |

| Positioning Accuracy | ±0.2 mm |

| Control System | CNC + PLC Touchscreen |

| Power Supply | 380V / 50Hz / 3 Phase |

| Total Power | Approx. 30 kW |

2. Advanced Punching System

The machine includes a multi-mode hydraulic punching station that supports interchangeable dies for different hole shapes and sizes. Its robust frame and high-pressure hydraulic cylinder allow for clean, deformation-free punching even on thick copper bars.

Punching Features:

Quick die change system for minimal downtime

Programmable patterns for complex configurations

Multi-hole punching in a single cycle

Reduced burrs and high edge precision

3. High-Precision Shearing Station

The shearing unit uses a hardened precision blade designed to deliver clean, straight cuts without distortion. With a shearing force of up to 800 kN, it can cut through copper and aluminum busbars with ease, ensuring minimal material waste.

Shearing Benefits:

Straight, smooth cuts

Minimal maintenance blade system

Hydraulic stability control

Safe double-hand operation (manual mode)

4. Servo Feeding System

A key differentiator of the MX602K-7/8C is its high-precision servo-driven feeding system. It ensures accurate positioning for both punching and shearing tasks and supports seamless transition between operations.

Key Highlights:

Closed-loop control with encoder feedback

Positioning accuracy up to ±0.2 mm

Fully programmable length and pattern logic

Adjustable feeding speed based on task requirements

5. CNC + PLC Control Panel

The machine is operated via a user-friendly touchscreen interface that combines CNC logic with programmable logic control (PLC) features. The system supports:

Graphical interface for intuitive programming

Multi-language support (English, Chinese, Spanish, etc.)

Pre-set templates for common busbar designs

Real-time error diagnostics and production tracking

USB data import/export for workpiece files

6. Structural Design and Build Quality

The MX602K-7/8C is designed with a robust, welded steel frame that reduces vibration during high-force operations. Each processing unit is precisely aligned to ensure reliable, long-term performance.

Design Advantages:

Compact machine footprint

Shock-absorbing base for improved stability

Modular station layout for future upgrades

Heavy-duty hydraulic cylinders with temperature control

7. Safety and Ergonomics

Lijian places a strong emphasis on operator safety and ease of use. The MX602K-7/8C includes:

Protective shields around moving parts

Emergency stop buttons at key positions

Hydraulic overload protection system

Optional light curtain safety barriers

8. Application Scenarios

The MX602K-7/8C is ideal for a wide range of industrial busbar processing needs:

Power transmission and distribution systems

Low-voltage switchgear and control cabinet assembly

Electrical panel and junction box manufacturing

Solar energy busbar setups

Smart grid infrastructure fabrication

Its ability to rapidly adapt to different busbar specifications makes it especially suited for OEMs, custom engineering firms, and mass production lines.

9. Operational Benefits

| Feature | Benefit |

|---|

| Dual-function integration | Saves floor space and cost |

| CNC interface | Simple operation and fast learning curve |

| High-strength punching | Handles thick busbars with ease |

| Shearing blade longevity | Low maintenance and downtime |

| Precision servo feed | Consistent, high-quality output |

| Modular components | Easier repair and expansion |

| Full automation optional | Reduces labor dependence |

10. Industry 4.0 Compatibility

The MX602K-7/8C is built with smart manufacturing in mind. It supports:

MES / ERP connectivity

Real-time production monitoring

Data logging for traceability and QC

IoT-based fault reporting and alerts

Remote diagnostics and maintenance support

This positions it as an ideal tool for digital factory integration and future-proof production environments.

11. Client Testimonials

Case Study – Smart Panel Manufacturer in Europe

After switching to MX602K-7/8C, output increased by 65% and tooling changeover time was reduced by 50%, enabling faster order turnaround with fewer operators.

Customer Feedback – Electrical Equipment OEM in Southeast Asia

“We chose Lijian for precision and stability. The MX602K-7/8C exceeded our expectations in durability and operational simplicity.”

12. Lijian Support and Service

Lijian provides global support for the MX602K-7/8C, including:

Installation and commissioning

Online and on-site training

Preventive maintenance packages

Local and international spare part dispatch

Technical upgrades and system extensions

Conclusion

The Lijian MX602K-7/8C Busbar Punching and Shearing Machine is a comprehensive and future-ready solution for electrical busbar processing. It integrates robust hardware, intelligent software, and high-speed servo systems into a versatile production platform capable of meeting the most demanding fabrication tasks.

Whether you're upgrading from manual operations or automating your existing production line, this machine offers the reliability, scalability, and intelligence required in today’s competitive industrial

RELATED

RELATED