I. Introduction:

1. Main use:

The main function of the machine is to perform arc machining on the end of copper busbar. It is mainly used for milling angle and arc angle of copper and aluminum busbars with thickness of 4-16mm and width of 30-200mm. It has simple structure with convenient use.

2. Control mode:

The electrical control is controlled by 5-axis CNC system. The feeding and cutting of copper busbar are completed through the

start-up of spindle motor and servo motor. The clamping or loosening of cutter is completed by pneumatic control.

The two-axis CNC automatic control system is adopted, and a 10.4"LCD is equipped, which can display the working state of the

machine tool. It has the functions of storing according to the input work number, calling the counting of workload, displaying and communicating, simulating processing, as well as online manual programming.

3. Machine tool structure, advantages and operation characteristics:

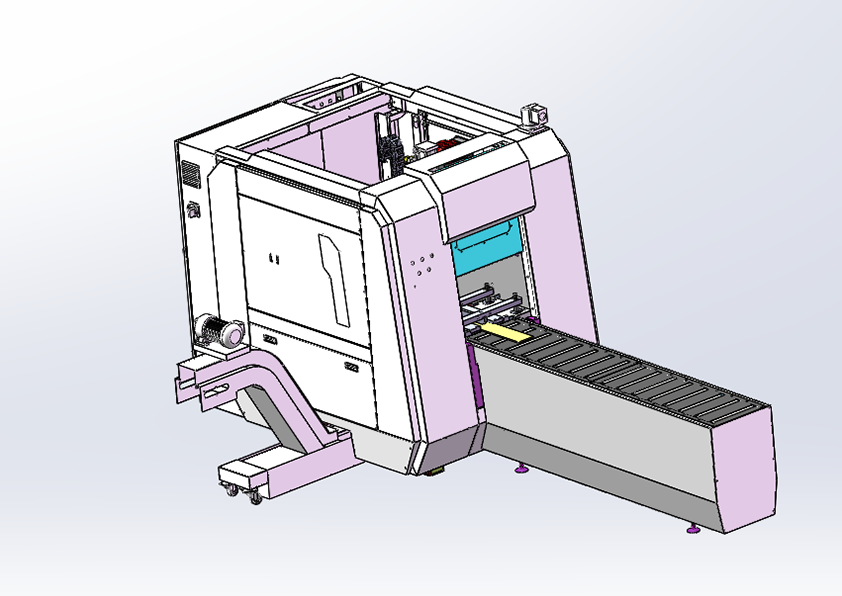

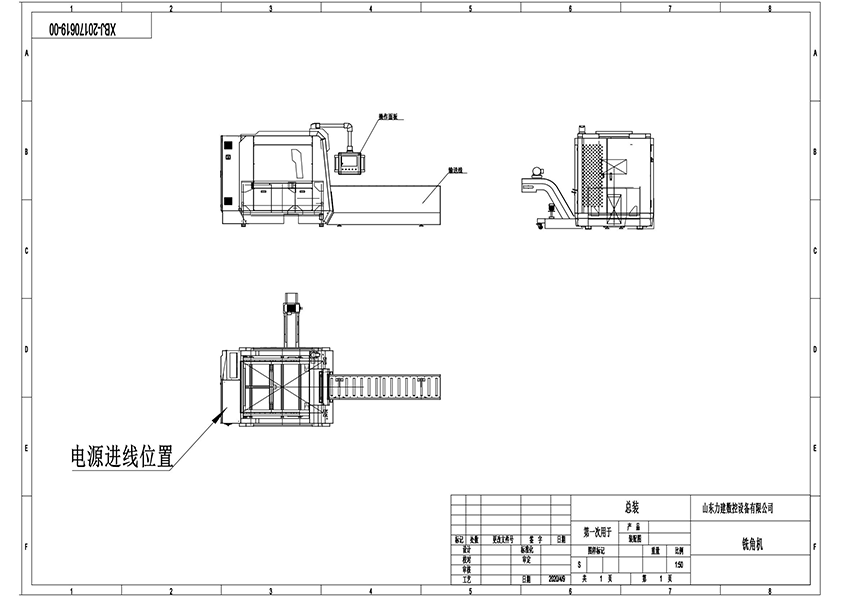

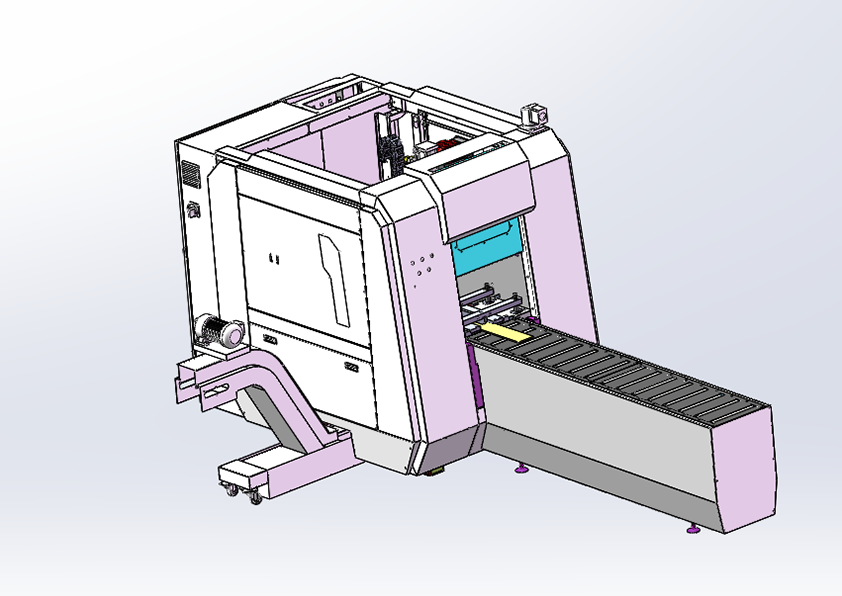

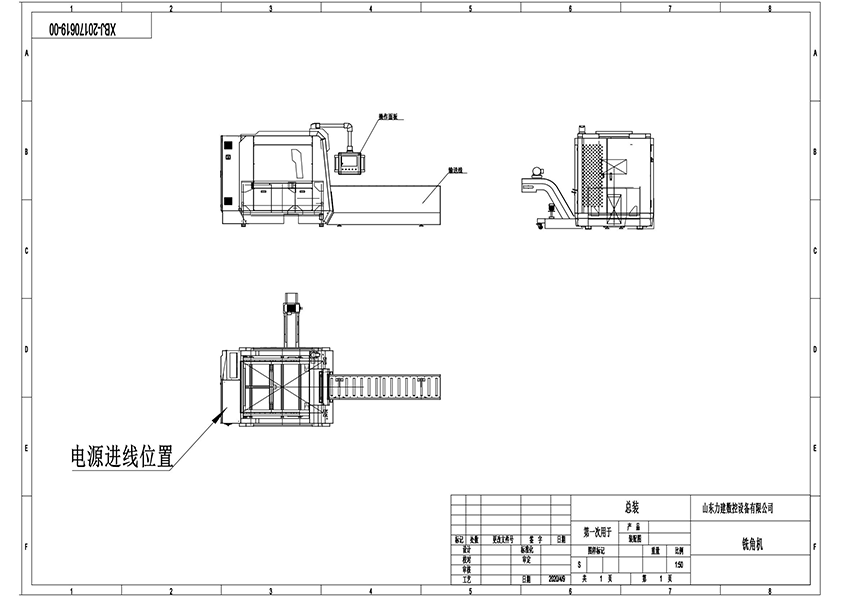

The machine is mainly composed of lathe bed workbench, gantry, slide rail, servo motor, power head and cylinder, fixture device, pneumatic system, CNC system, protective cover, etc.

Gantry-type mechanical structure adopts steel plate full-welded box structure, whose advantages are good rigidity and light weight of the lathe bed, meeting the requirements of rigidity of strong cutting of main spindle cutting tool and the requirement of sensitive feed response of moving parts.

The machine adopts high-precision ball screw and linear guide, and adopts high-load large-size guide in the selection of guide, making a better rigidity of the whole machine, reducing the vibration and noised, improving the work-piece quality, and ensuring the high precision and efficiency.

The spindle of the machine tool adopts the high-precision high-speed milling machine main shaft which is installed integrally, and is driven by the variable-frequency motor with stepless speed change and the synchronous belt. It has the characteristics of simple and reliable transmission structure, no need of lubrication, convenient cooling, high installation precision, high cutting speed and the like.

A three-point positioning mode is adopted for workpiece positioning. After the workpiece is positioned, the workpiece is clamped by a workpiece clamping mechanism. The workpiece clamping mechanism adopts both pneumatic and hydraulic clamping, and has stable speed without impact, reliable clamping force and easy adjustment.

The longitudinal (Y-direction) transmission and guide system of the machine tool is equipped with an organ-type protective cover to prevent flying dust from polluting the equipment.

The lathe bed is equipped with an in-line cutting tool magazine with six stations, which is convenient for the replacement and placement of commonly used working cutting tools.

The bottom of the machine tool body is provided with a chip collecting groove and a chip collecting trolley, which not only facilitates the collection of metal chips, but also saves the occupied area of the machine tool. Meanwhile, the device is simple and reliable.

The machine has the function of automatically accumulating working hours that cannot be reset. In addition, it has production counting function that can be reset.

The cutting tool of this machine adopts the formed cutting tool shearing. The cutting tool adopts the BT40 tool handle of the international standard with simple tool changing, good rigidity, and high precision. The in-line cutting tool magazine with six stations can automatically change the cutting tool according to the thickness of the busbar.

The machine is equipped with a water circulation system, and an automatic chip removal system is added.

The used components are well-known brands at home and abroad, with long service life and quality assurance.

I. Main technical parameters:

| Serial No. | Parameter Name | Unit | Parameter Value | Remarks |

| 1 | Maximum spindle speed | r/min | 6000 |

|

| 2 | Main motor power | KW | 3.7 |

|

| 3 | Model of spindle handle |

| BT40 |

|

| 4 | X-axis working stroke | mm | 525 | Ensure that the copper busbar within the range of R100 can be machined |

| 5 | Y-axis engineering stroke | mm | 500 | Ensure that the copper busbar within the width of 160 can be machined. |

| 6 | Maximum operating speed of X-axis | m/min | 15 |

|

| 7 | Maximum operation speed of Y-axis | m/min | 15 |

|

| 8 | X-axis positioning accuracy | mm | ±0.08 |

|

| 9 | Y-axis positioning accuracy | mm | ±0.08 |

|

| 10 | Machinable workpiece thickness | mm | 4-16 | 4-16 |

| 11 | Machinable workpiece thickness width | mm | 30-200 |

|

| 12 | Machinable workpiece thickness length | mm | 150-6000 |

|

| Control mode |

| 1 | Number of CNC axes | Piece | 5 |

|

| 2 | Power of X-axis servo motor | KW | 2 |

|

| 3 | Power of Y-axis servo motor | KW | 2 |

|

| 4 | Hydraulic pump motor power | KW | 2 |

|

| 5 | Working pressure of pneumatic system | MPa | 0.6-0.8 |

|

| 6 | Overall dimensions of machine tool | mm | 2260×1580×2100 |

|

| 7 | Machine weight | Kg | 2380 |

|

| 8 | Total power | KW | 12 |

|

III. Catalogue of Main Purchased Parts:

| Serial No. | Name | Quantity | Brand |

| 1 | Ball screw | 4 sets | HIWIN/TBI |

| 2 | Linear rolling guide | 8 sets | HIWIN/PEK |

| 3 | Servo driver | 4 sets | Rexroth |

| 4 | Servo motor | 4 sets | Rexroth |

| 5 | Pneumatic parts | 1 set | HSBC |

| 6 | Hydraulic components | 1 set | Shanghai Fengyi |

| 7 | Spindle servo | 1 set | Jing Yao |

| 8 | Programmable controller | 1 set | BECKHOFF, Germany |

IV. Accessories

6 milling cutters (standard configuration: 4, 5, 6, 8, 10, 12), one set of attached tools, one set of instructions and one set of certificate.

LJMN-200 Copper Busbar Arc Machining Center: Precision Bending for Modern Power Systems

Introduction

The LJMN-200 Copper Busbar Arc Machining Center is a state-of-the-art CNC machine designed for high-precision arc processing of copper and aluminum busbars used in power transmission and electrical control systems. As an advanced bending and forming solution developed by Lijian, the LJMN-200 enables seamless fabrication of circular, arc, and complex busbar shapes, streamlining the manufacturing process for switchgear cabinets, electrical panels, and smart grid components.

With unmatched bending accuracy, intelligent CNC control, and robust mechanical performance, the LJMN-200 offers superior consistency, labor efficiency, and integration capabilities for modern industrial operations.

1. Product Overview

The LJMN-200 Arc Machining Center is purpose-built for forming arcs in flat busbars. It operates on fully automated servo and hydraulic systems, offering an ideal solution for companies demanding scalable production capacity with minimal manual intervention.

Whether fabricating small-radius arcs or large sweeping curves, the LJMN-200 delivers excellent forming results for busbars up to 200mm in width and 15mm in thickness.

Core Specifications

| Parameter | Value |

|---|

| Max Busbar Width | 200 mm |

| Max Busbar Thickness | 15 mm |

| Min Bending Radius | R30 mm |

| Max Bending Radius | R1000 mm (customizable) |

| Arc Angle Range | 0° - 360° |

| Bending Accuracy | ±0.2° |

| Workpiece Material | Copper, T2 copper, Aluminum |

| Control System | CNC + Touchscreen Interface |

| Motor Power | 15-30 kW |

| Hydraulic Pressure | Up to 25 MPa |

| Machine Dimensions | Approx. 3500 × 1800 × 1600 mm |

| Total Weight | ~2.8 tons |

2. Intelligent CNC Control System

At the heart of the LJMN-200 is an intelligent CNC platform that controls every movement with precision. The user-friendly interface allows operators to program arc shapes, radii, and positions through a touchscreen display or external CAD file import.

Features:

Multi-language interface

Automatic calculation of arc parameters

Real-time simulation preview

Preset memory for frequent shapes

USB/SD card program input

Cloud remote diagnostics (optional)

3. Arc Forming Mechanism

The machine utilizes multi-axis servo coordination to ensure high-precision arc forming. Its specialized arc forming unit applies gradual and even force to prevent material deformation, cracks, or springback.

System Highlights:

Servo-driven roller feed with feedback control

Advanced hydraulic clamping and positioning system

Arc compensation algorithms

Supports inner, outer, and compound arc forming

Automatic calibration to adjust radius deviation

4. Processing Capacity

The LJMN-200 is engineered to meet the needs of both large-scale production and customized busbar designs. It supports:

Small radius bends for compact switchgear layouts

Large arc segments for curved busbar ducts

Multi-radius combination arcs

Compound curves and spiral transitions

Batch processing with minimal tolerance loss

5. Robust Structural Design

Built with a rigid welded steel frame and precision-machined guide rails, the LJMN-200 ensures stability and durability over years of heavy-duty use. Each mechanical component is tested under simulated load conditions to ensure reliability.

Construction Features:

Heavy-duty steel housing with vibration damping

Precision linear guideways and ball screws

Surface-treated components to resist oxidation

Low-noise hydraulic components

Floor-mounted design for stability

6. Safety and Ergonomics

Designed to ensure operator safety and ease of use:

Protective enclosures around moving parts

Foot pedal activation for clamping control

Two-hand control for bending process (manual mode)

Emergency stop switches at strategic locations

Auto-shutdown on overload or fault detection

7. Software Integration and Automation

The LJMN-200 supports:

CAD/CAM import compatibility (DXF, DWG formats)

MES system integration for smart workshop environments

Remote update of system firmware

IoT module for cloud monitoring (optional)

These capabilities make it an essential part of Industry 4.0-ready fabrication lines.

8. Applications

The LJMN-200 Copper Busbar Arc Machining Center is used extensively in:

Power distribution panel manufacturing

Low-voltage and high-voltage switchgear production

Wind and solar inverter systems

New energy vehicle power modules

Smart grid infrastructure

Industrial control cabinet production

Its versatility makes it suitable for OEM production, custom prototyping, and large-volume repetitive tasks.

9. Benefits for Manufacturers

| Feature | Benefit |

|---|

| High-precision bending | Reduces error and rework |

| CNC automation | Increases production speed |

| Energy-efficient operation | Lower operational cost |

| Compact footprint | Saves factory space |

| Multiple arc types supported | Wider product compatibility |

| One-operator workflow | Reduced labor cost |

| Long-term durability | Lower maintenance downtime |

10. Customer Feedback and Case Studies

Large Switchgear Manufacturer - South Korea:

“The LJMN-200 allowed us to achieve consistent arc accuracy within 0.2 degrees. Output rose by 45% after integration.”

Smart Grid Integrator - Germany:

“We replaced two manual arc machines with one LJMN-200. The digital control and repeatability changed our production reliability completely.”

11. Installation, Training, and After-Sales Support

Lijian offers full lifecycle support for the LJMN-200, including:

On-site installation and calibration

Operator training (in-person and remote)

Spare parts supply worldwide

Maintenance contracts and warranty extensions

24/7 remote diagnostics and tech support

12. Optional Accessories and Upgrades

To increase versatility, the LJMN-200 can be upgraded with:

Dual-radius arc module

Cooling spray system for high-load operations

Barcode scanner and MES connectivity

Uncoiler and feeding rack for continuous busbar supply

Automatic stacking or discharge conveyor

Conclusion

The LJMN-200 Copper Busbar Arc Machining Center is a powerful, intelligent, and flexible tool that supports the evolving demands of modern electrical equipment manufacturing. Its precision arc forming, CNC automation, and structural stability make it a must-have asset for companies seeking to scale their operations while maintaining tight quality control.

Backed by Lijian’s proven engineering and global support, the LJMN-200 represents the future of Busbar bending technology.