I. Introduction:

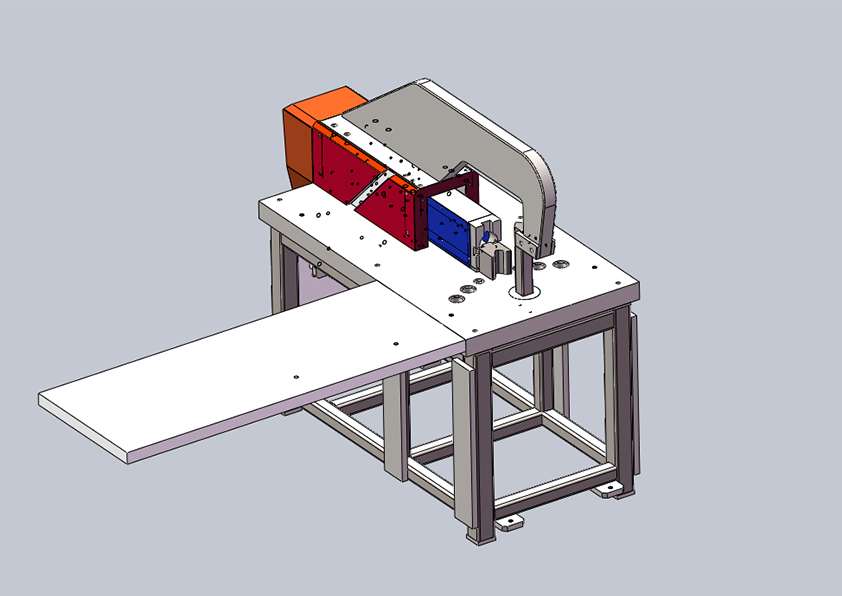

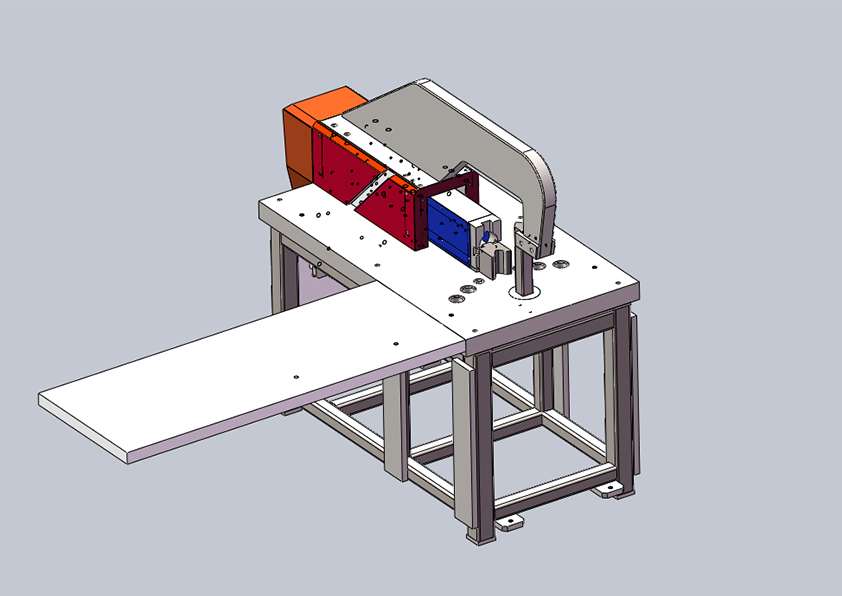

The NC.40ZB-1200 CNC busbar bending machine is an efficient, highly automated, and high-precision equipment used for bending copper and aluminum busbars. The machine is powered by servo motors, controlled by CNC units, and equipped with a self-developed CAD/CAM software system. This ensures that the machine's level of automation is at the forefront of the industry. It is an ideal equipment for busbar processing in industries such as complete sets of high and low voltage equipment, box-type substations, transformers, and busbar slots.

The machine adopts large inertia servo motor as the main power to provide transmission power for high-precision planetary reducer and grinding ball screw.

Compared with the traditional hydraulic bending machine, it has the following advantages:

1.The transmission is stable, the repeated positioning precision is high, the precision is not influenced by the temperature, and the stability is higher

2. Automatic stop function is available in standby mode, which greatly reduces working energy consumption.

3. The machine adopts servo motor as power, solving the trouble of oil leakage caused by hydraulic transmission.

4. When working, the sound of the servo motor is low, reducing the noise pollution.

5. It has the centering capacity carrying mode, and the linear guide, which balance the stress, and reduce the influence of eccentric load and friction on the service life and processing precision of the lead screw.

6. The material stopping ruler is divided into three gears, which can be adjusted manually according to the processing technology, thereby greatly improving the working efficiency.

II. Selection of main accessories:

| 1 | Servo motor | Rexroth | 1 pc. | 2 | Spindle lead screw | Nanjing Technological Equipment | 1 pc. |

| 3 | Precision planetary speed reducer | TECHMECH | 1 pc. | 4 | Linear guide | HIWIN/PEK | 5 pcs |

| 5 | AC contactor | Siemens, Germany | 1 pc. | 6 | Computer | Beijing Qiyang | 1 pc. |

| 7 | Positioning lead screw | TBI, Taiwan | 1 pc. | 8 | Industrial switch | TP-LINK | 1 pc. |

| 9 | Programmable controller | Beckhoff, Germany | 1 pc. | Blank here |

III. Parameter comparison:

| 1 | Nominal pressure | kN | 400 | 2 | Spindle motor power | kW | 7.5 |

| 3 | Bending accuracy | ° | ±0.3 | 4 | Spindle stroke | mm | 200 |

| 5 | Material blocking accuracy | mm | ±0.15 | 6 | Max. size of flat bending | mm | 15×160 |

| 7 | Max. size of vertical bending | mm | 12×120 | 8 | Material blocking length | mm | 1200 |

| 9 | Machine weight | kg | 3100 | 10 | Appearance and size | mm | 3500×1450×1850 |

IV. Accessories:

| 1 | Flat bending core | R5 | 1 pc. | 2 | Flat bending core | R10 | 1 pc. | 3 | Flat bending cavity | 50mm | 1 pc. |

| 4 | Flat bending cavity | 80mm | 1 pc. | 5 | Vertical bending core | R30 | 1 pc. | 6 | Vertical bending core | R100 | 1 pc. |

| 7 | Vertical bending inserting shaft |

| 4 pcs. | 8 | Accompanying tools | 1 set | Blank below |

V. Quality Service:

1.The warranty period is one year. In case of any quality problem within the warranty period, the on-site service shall be provided unconditionally within 24 hours.

2.All mold parts are guaranteed for three months. In case of quality problems within three months, they shall be returned or replaced unconditionally.

3.We provide free delivery, and free debugging training until the mastering of the machine.

NC. 40ZB-1200 CNC busbar bending machine: High Precision Bending for Modern Electrical Manufacturing

Introduction

In the rapidly advancing field of electrical equipment manufacturing, precision and efficiency are critical. The NC. 40ZB-1200 CNC Busbar bending machine is an advanced solution tailored for high-accuracy bending of copper and aluminum busbars. Designed with cutting-edge CNC control technology and a robust mechanical structure, this machine enhances productivity, reduces material waste, and ensures consistent bending quality. It is ideal for applications in switchgear production, power distribution equipment, and electrical panel assembly.

1. Product Overview

The NC. 40ZB-1200 is a numerically controlled busbar bending machine that combines servo precision with hydraulic strength. It offers versatile bending capabilities including flat, vertical, and twisted bends, supporting a wide range of busbar sizes. Its intelligent interface allows operators to easily set angles, positions, and batch sequences with minimal training.

Key Specifications:

Model: NC. 40ZB-1200

Max Bending Force: 400 kN

Max Busbar Width: 120 mm

Max Busbar Thickness: 15 mm

Bending Angle Range: 0° – 180°

Control System: CNC + PLC with touchscreen interface

Motor Power: 5.5 kW (or customized based on application)

Working Table Size: Optimized for multiple busbar sizes

2. Core Features

2.1 Advanced CNC System

At the heart of the NC. 40ZB-1200 is a high-precision CNC controller. It ensures exact angle positioning with programmable memory functions for batch jobs. The system stores multiple bending programs and allows quick setup for different projects.

2.2 Hydraulic and Servo Drive Integration

The hybrid hydraulic-servo system provides the necessary force for thick busbar bending while maintaining precise positioning. Servo motors control the bending axis with exceptional repeatability, even under high workloads.

2.3 Robust Clamping System

The machine uses a dual-action hydraulic clamping mechanism that firmly holds the busbar during operation, preventing slipping or misalignment. This ensures bending accuracy and operator safety.

2.4 User-Friendly Interface

The machine features a multilingual touchscreen HMI that offers easy navigation, real-time diagnostics, error alerts, and production tracking. This simplifies training and reduces human error.

2.5 Modular Structure

The NC. 40ZB-1200 has a modular mechanical design, which allows easy maintenance and potential upgrades. All critical components are easily accessible, improving service efficiency.

3. Application Scenarios

This CNC busbar bending machine is widely used in the electrical, power, and mechanical industries. Typical applications include:

Switchgear manufacturing

Electrical control panel production

Transformer busbar bending

Railway electrification systems

Renewable energy power stations (solar/wind)

Its flexibility and precision make it ideal for both large-scale production lines and custom electrical system fabrication.

4. Benefits and Advantages

4.1 Increased Efficiency

With its automatic operation and programmable settings, the NC. 40ZB-1200 drastically reduces setup time and production cycles. Multiple bends can be completed with a single positioning, increasing daily output.

4.2 Superior Accuracy

Thanks to the servo-driven control and real-time feedback system, this machine offers bending accuracy up to ±0.2°, even for complex geometries.

4.3 Cost Savings

By minimizing material waste and reducing labor input, the NC. 40ZB-1200 lowers overall production costs. It also reduces the need for rework due to inaccurate bends.

4.4 Space-Saving Design

Its compact footprint makes it suitable for both large workshops and small-to-medium manufacturing spaces.

4.5 Enhanced Safety

The machine includes emergency stop systems, sensor-based protections, and operational interlocks to ensure safe use. Protective enclosures over moving parts further reduce injury risk.

5. Technical Integration and Smart Manufacturing

The NC. 40ZB-1200 supports integration with smart factory systems:

Ethernet and USB connectivity

ERP system compatibility

Remote diagnostics and software updates

Data logging for quality control and traceability

This enables manufacturers to bring busbar production into the digital age, aligning with Industry 4.0 standards.

6. Maintenance and Service Life

The machine is engineered for longevity with minimal maintenance:

Automatic lubrication system

Wear-resistant components

Real-time service notifications

Remote troubleshooting support

With regular care, the machine can maintain peak performance for over 10 years in a continuous-use environment.

7. Operator Training and Technical Support

To ensure smooth adoption, most suppliers offer comprehensive support services, including:

On-site installation and commissioning

Training for operators and maintenance personnel

Access to detailed manuals and video tutorials

Lifetime technical support and spare parts availability

8. Comparison with Similar Models

Compared to semi-automatic or manual bending machines, the NC. 40ZB-1200 stands out in terms of:

| Feature | Manual Bending | Semi-Auto | NC. 40ZB-1200 |

|---|

| Precision | Low | Medium | High |

| Speed | Slow | Moderate | Fast |

| Automation | None | Partial | Full |

| Material Waste | High | Medium | Low |

| Operator Skill Needed | High | Moderate | Low |

9. Environmental Considerations

Built with eco-efficiency in mind, the NC. 40ZB-1200 includes:

Low power consumption motors

Reduced oil leakage through sealed systems

Noise suppression technology

Compatibility with green production environments

10. Customer Feedback

Many manufacturers report a significant increase in busbar processing efficiency after adopting the NC. 40ZB-1200. Common feedback includes:

“Reduced our processing time by 40%.”

“Excellent angle consistency, even with thick copper busbars.”

“User interface is simple and very responsive.”

“Solid machine build quality — it runs 12 hours a day with no problem.”

Conclusion

The NC. 40ZB-1200 CNC Busbar Bending Machine is a powerful, precise, and cost-effective solution for modern busbar fabrication. With its advanced CNC control, durable structure, and smart integration features, it meets the demands of high-volume and high-accuracy electrical manufacturing.

Investing in the NC. 40ZB-1200 means upgrading your production line with reliable automation, reducing labor costs, increasing output, and ensuring the highest quality standards in every bend.

RELATED

RELATED