I. Introduction:

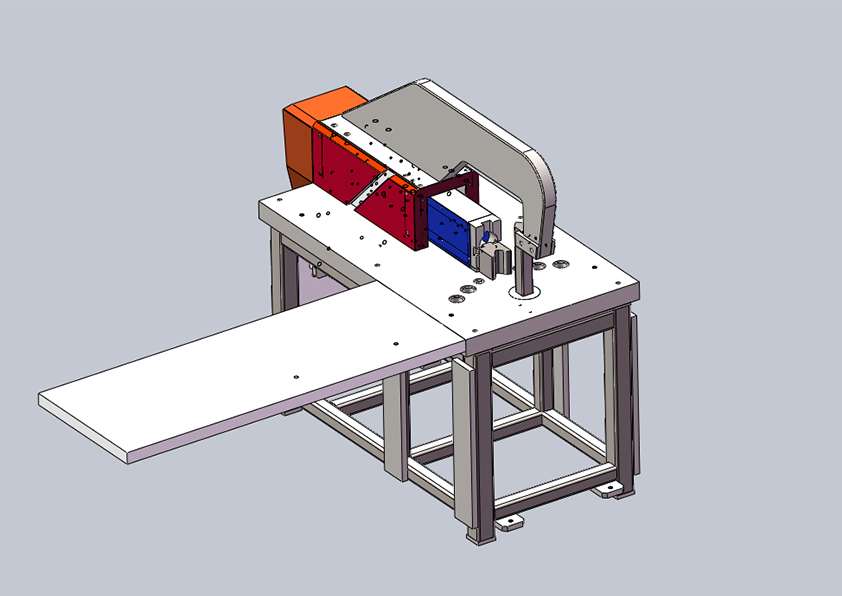

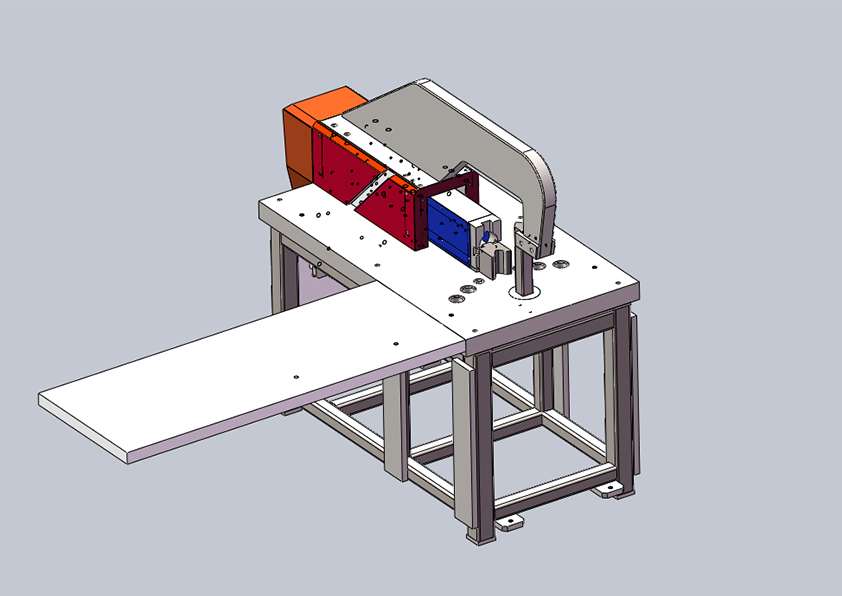

The NC.40ZB-2000 CNC busbar bending machine is an efficient, highly automated, and high-precision equipment used for bending copper and aluminum busbars. The machine is powered by servo motors, controlled by CNC units, and equipped with a self-developed CAD/CAM software system. This ensures that the machine's level of automation is at the forefront of the industry. It is an ideal equipment for busbar processing in industries such as complete sets of high and low voltage equipment, box-type substations, transformers, and busbar slots.

The machine adopts large inertia servo motor as the main power to provide transmission power for high-precision planetary reducer and grinding ball screw.

Compared with the traditional hydraulic bending machine, it has the following advantages:

1.The transmission is stable, the repeated positioning precision is high, the precision is not influenced by the temperature, and the stability is higher.

2.Automatic stop function is available in standby mode, which greatly reduces working energy consumption.

3.The machine adopts servo motor as power, solving the trouble of oil leakage caused by hydraulic transmission.

4.When working, the sound of the servo motor is low, reducing the noise pollution.

5.It has the centering capacity carrying mode, and the linear guide, which balance the stress, and reduce the influence of eccentric load and friction on the service life and processing precision of the lead screw.

6.The material stopping ruler is divided into three gears, which can be adjusted manually according to the processing technology, thereby greatly improving the working efficiency.

II. Selection of main accessories:

| 1 | Servo motor | Rexroth | 1 pc. | 2 | Spindle lead screw | Nanjing Technological Equipment | 1 pc. |

| 3 | Precision planetary speed reducer | TECHMECH | 1 pc. | 4 | Linear guide | HIWIN/PEK | 5 pcs |

| 5 | AC contactor | Siemens, Germany | 1 pc. | 6 | Computer | Beijing Qiyang | 1 pc. |

| 7 | Positioning lead screw | TBI, Taiwan | 1 pc. | 8 | Industrial switch | TP-LINK | 1 pc. |

| 9 | Programmable controller | Beckhoff, Germany | 1 pc. | Blank here |

III. Parameter comparison:

| 1 | Nominal pressure | KN | 400 | 2 | Spindle motor power | KW | 7.5 |

| 3 | Bending accuracy | ° | ±0.3 | 4 | Spindle stroke | mm | 200 |

| 5 | Material blocking accuracy | mm | ±0.15 | 6 | Maximum size of flat bending | mm | 15×200 |

| 7 | Maximum size of vertical bending | mm | 12×120 | 8 | Material blocking length | mm | 2000 |

| 9 | Machine weight | KG | 3300 | 10 | Appearance and size | mm | 4300×1450×1850 |

IV. Accessories:

| 1 | Flat bending core | R5 | 1 pc. | 2 | Flat bending core | R10 | 1 pc. | 3 | Flat bending cavity | 50mm | 1 pc. |

| 4 | Flat bending cavity | 80mm | 1 pc. | 5 | Vertical bending core | R30 | 1 pc. | 6 | Vertical bending core | R100 | 1 pc. |

| 7 | Vertical bending inserting shaft |

| 4 pcs. | 8 | Accompanying tools | 1 set | Blank below |

V. Quality Service:

1.The warranty period is one year. In case of any quality problem within the warranty period, the on-site service shall be provided unconditionally within 24 hours.

2.All mold parts are guaranteed for three months. In case of quality problems within three months, they shall be returned or replaced unconditionally.

3.We provide free delivery, and free debugging training until the mastering of the machine.

NC. 40ZB-2000 CNC busbar bending machine: Precision, Efficiency, and Smart Manufacturing Integration

Introduction

The NC. 40ZB-2000 CNC Busbar bending machine represents the next evolution in intelligent Busbar processing equipment. Designed for high-volume, high-precision industrial applications, this machine leverages advanced CNC technology to deliver consistent, automated busbar bending with exceptional accuracy. Whether you're operating in a power distribution plant, electrical cabinet workshop, or heavy-duty manufacturing facility, the NC. 40ZB-2000 offers unmatched speed, reliability, and control.

1. Overview of the NC. 40ZB-2000

The NC. 40ZB-2000 is a fully automated CNC busbar bending machine that supports multi-directional bending, angle adjustments, and complex shape programming. Engineered with a high-strength frame, servo-electric actuation, and intuitive HMI control, this machine is ideal for companies seeking enhanced productivity with minimal manual intervention.

Key Specifications:

Model: NC. 40ZB-2000

Max bending force: 400kN

Max busbar width: 200mm

Max busbar thickness: 15mm

Bending angle range: 0°–180°

Bending speed: Adjustable via CNC control

Control system: Industrial-grade touchscreen with PLC

2. Core Features and Technology

2.1 CNC Precision Bending

At the heart of the NC. 40ZB-2000 is its CNC-controlled bending system. With pre-programmed bending parameters and servo drive control, the system ensures precise bending angles and repeatability across large batches. Users can input custom designs, angles, and sequences, significantly reducing human error and rework.

2.2 Hydraulic and Servo Drive Hybrid

This machine integrates a hybrid system that uses both hydraulic force and servo-driven precision. The hydraulic component offers powerful bending force, while the servo system provides accurate positioning and feedback control.

2.3 Intelligent Touchscreen Interface

The intuitive HMI interface supports multi-language operation, real-time diagnostics, angle visualization, and job memory. Operators can easily manage bending sequences, monitor pressure and speed, and update software for improved functionality.

2.4 High-Strength Structure and Worktable

Crafted from thick-walled steel and precision-machined, the worktable supports heavy-duty busbars without deformation. Anti-rust coating and anti-slip clamping devices ensure long service life and stability during operation.

3. Applications

The NC. 40ZB-2000 CNC Busbar Bending Machine is widely used in industries that demand precise copper and aluminum busbar shaping. Applications include:

Electrical switchgear assembly

Power transformer manufacturing

Electric control cabinet production

Renewable energy systems (solar, wind)

Railway and transportation electrification

Its versatility makes it ideal for both standard and complex busbar projects.

4. Advantages Over Traditional Bending Machines

4.1 Increased Automation

Manual bending machines rely heavily on operator experience and are prone to inconsistencies. The NC. 40ZB-2000 eliminates these issues by automating the entire bending process, allowing for batch consistency and low skill dependency.

4.2 Enhanced Safety Features

Equipped with sensors, emergency stops, and automatic shut-off systems, the machine minimizes workplace hazards. The enclosed bending unit further protects operators from direct exposure to moving components.

4.3 Reduced Material Waste

Accurate angle control and digital feedback ensure optimal material usage, significantly cutting down on scrap rates. This not only lowers material costs but also contributes to greener manufacturing practices.

5. Integration with Digital Manufacturing

This busbar bending machine supports Industry 4.0 integration. Through its Ethernet and USB ports, it can:

Connect to factory ERP systems

Export/import data via cloud or local servers

Enable remote diagnostics and updates

Record operation logs for quality control

6. Maintenance and Longevity

Built for continuous industrial operation, the NC. 40ZB-2000 includes low-maintenance components like sealed bearings, high-lubricity surfaces, and modular electronics. Its preventive maintenance interface provides reminders for part checks, fluid levels, and firmware updates.

7. Technical Support and Training

Manufacturers typically offer:

On-site commissioning and calibration

Operator training sessions

Lifetime technical support

Access to spare parts and firmware upgrades

This ensures smooth integration and long-term use for any production line.

8. Conclusion

For manufacturers seeking precision, power, and performance in busbar processing, the NC. 40ZB-2000 CNC Busbar Bending Machine is a game-changer. It delivers speed, safety, and accuracy that manual or semi-automated systems simply cannot match.

Whether you're modernizing your factory or scaling up production, this machine offers a future-ready solution to streamline busbar fabrication and improve product consistency.

RELATED

RELATED